About Joe

After many years of building heavy agricultural and industrial machinery my interests strayed & I began looking into the artistic side of working with steel. Given the nature of what I had been doing previously & the fact that there was a consistent demand to manufacture to the highest standards both in quality of workmanship & the materials being used, this naturally flowed through to my current work. However there has always been, though much stronger in recent years a drive to use wherever possible Australian made steel. I believe that not only does the client end up with a superior product but also that in doing so we are hopefully in some small way preserving the pioneering industry that Australia was built upon.

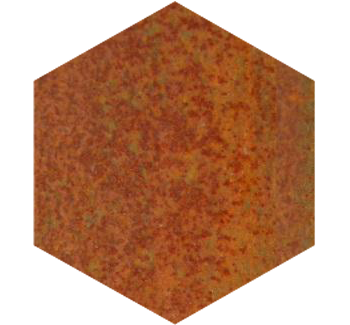

Predominantly the material of choice for Steelscape is Aussie made Corten steel which in fact is not just steel at all. It is a combination of steel, nickel & copper. These when combined give a material that rusts on the surface but is extremely resistant to corrosion & doesn’t break down as mild steel normally would. The end result is varied patina across the surface of the corten that can have amazing visual representations on structures & in landscaped areas.

Some of the products that we started with were metal screens to be used for signage, privacy, garden features or even lightboxes. We then extended the range to gates, 3D letters & numbers, letterboxes of any shape & design & firepits. The real direction that we now pursue though is sculptural. Predominantly with just the corten but now using horseshoes, stainless steel, translucent Perspex & even custom blown glass. The best part is these are only limited in design by imagination. We work with our clients to design pieces that are considered & long lasting.

Where We Started

A passion for working with steel that has been developed over two generations of building heavy duty agricultural equipment in a family owned business has lead to this. We use our knowledge gained from steel products tested in the harshest environments to craft delicate yet strong functional pieces for our clients. A background that was forged from working on the land & merged into well thought custom design & production.

Custom Design

Most of our business is designed and manufactured from your ideas creatively developed by us with your needs in mind. We can re-scale, re-size, add signage, add patterns or delete to achieve your individual Requirements. Additional services offer lighting, finish, colour options and/or perspex.

Materials we work with

Corten is the material of choice for most of our work due to its alloy properties of corrosion resistance whilst still having a rusted organic finish. We choose to use only Australian made Corten steel even at double the cost of the imported equivalent as this keeps Aussie jobs & we believe we are giving you a superior product.

What is Plasma Cutting

Plasma cutting is a process that is used to cut steel and other metals of different thicknesses (or sometimes other materials) using a plasma torch. In this process, a gas (oxygen, air, inert and others dependent on material) is blown at high speed out of a nozzle; at the same time an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma. The plasma is hot enough to melt the metal being cut and moves fast enough to blow molten metal away from the cut.

Finishes

People think of steel as a hard cold surface that is industrial to look at, but in truth it can blend in a variety of environments inside & outside to add contrast & effect depending on the finish. Finishes we offer are constantly expanding & include;

Raw Steel

Dark grey in colour, this will add contrast to a lighter background but must be sealed to prevent rusting.

Powder Coating

This not only protects the steel but can integrate it into the surrounding environment. Available in a large range of colours.

Prerusted Corten

(with or without clear sealer) A technique we developed, rust normally takes months to achieve & is very monotone in its appearance. Prerusting accelerates this process to a matter of days & gives us the control to manipulate the patina as desired. For indoor pieces we can add a clear sealer.

Stainless Steel

Once again for contrast but typically in seaside environments stainless steel can be a great feature & with if required marine grade protection from the elements.